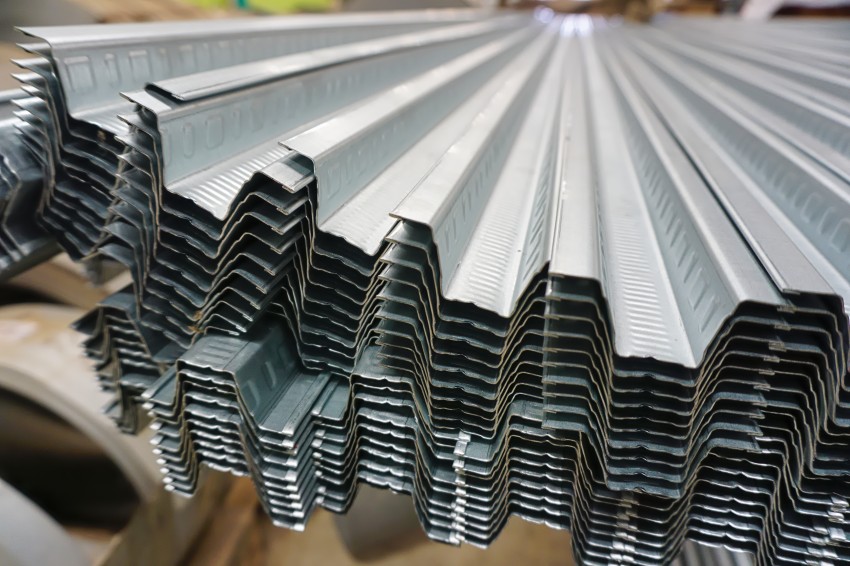

Alu-Zinc Coated Steel (GL)

The composition of the plating layer of the galvalume steel sheet is made of 55% aluminum, 43.4% zinc, and 1.6% silicon by weight ratio, and it is the most ideal combination of sacrificial corrosion resistance, alkali resistance, and durability, heat resistance, and acid resistance, which are the advantages of aluminum. Product.

Need a consultation?

Send a requestA. Characteristics:

|

Product introduction |

|

Detail view off |

|

Excellent Durability |

|

GL is three to six times more corrosion resistant than zinc coated steel sheet of the same thickness. |

|

Heat Resistance |

|

The capacity ratio of the aluminum in the coated layer of GL is high at over 80%. GL will withstand a prolonged temperature of 315 degrees Celsius without discoloration or oxidization. |

|

Heat Reflectivity |

|

GL is highly energy efficient, with superior heat reflectivity and low heat consumption. |

|

Smooth surface |

|

GL is available in a delicate light silver spangle, so it is appropriate for decorative use. |

|

Economically Efficient |

|

Available in widths of five feet (MAX 1600), GL reduces the loss and suite to duct and construction. |

|

Excellent paintability |

|

Paint is highly adhesive to the coated layer of GL steel sheet, compared to galvanized steel plates |

|

Excellent Workability |

|

The workability of GL is similar to that of galvanized steel sheet. Its ability to suppress fine cracks on the coating layer enhances the durability of the treatment area. |

B. Classification by Coating Weight:

|

Classification by Coating Weight |

|||||

|

Classification by Coating Weight |

|||||

|

KS |

ASTM |

EN |

Single-sided coating |

Double-sided |

|

|

thickness(㎛) |

Triple-Spot Test |

Single-Spot Test |

|||

|

AZ 70 |

- |

- |

9 |

70 |

66 |

|

AZ 70 |

- |

- |

12 |

90 |

77 |

|

- |

- |

100 |

13 |

100 |

85 |

|

AZ 120 |

- |

- |

16 |

120 |

102 |

|

AZ 150 |

AZM 150 AZ50 |

150 |

20 |

150 |

130(KS:128) |

|

- |

AZM 150 AZ50 |

- |

22 |

165 |

150 |

|

AZ 170 |

- |

- |

22 |

170 |

145 |

|

- |

AZM 150 AZ50 |

- |

24 |

180 |

155 |

|

- |

- |

185 |

25 |

185 |

160 |

|

AZ 200 |

- |

- |

26 |

200 |

170 |