Stainless Steel Sheet

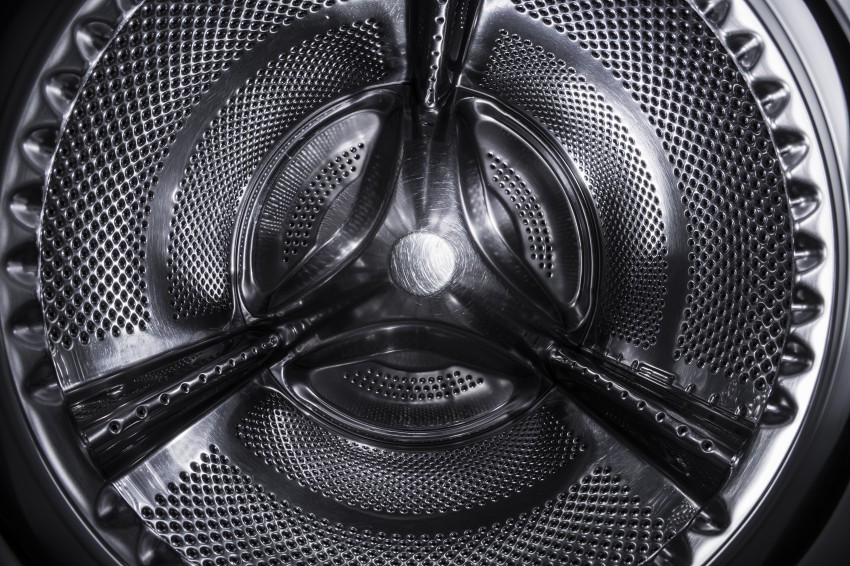

Stainless steel sheets are widely used in kitchen appliances, building exterior and interior materials, electrical appliances and chemical and heavy industries because they have excellent corrosion resistance and a beautiful surface without plating or painting.

Need a consultation?

Send a requestA. Specificatiom :

|

Austenitic |

Ferritic |

||

|

TYPE |

COMPOSITION |

TYPE |

COMPOSITION |

|

304 |

18Cr-8Ni |

409L |

11Cr-0.2Ti-LCN |

|

304L |

18Cr-9Ni-LC |

430 |

16Cr-0.05C |

|

304J1 |

17Cr-8Ni-2Cu |

430J1L |

19Cr-0.5Cu-0.4Nb-LCN |

|

316 |

18Cr-12Ni-2Mo |

439 |

18Cr-0.4Ti-LCN |

|

316L |

18Cr-12Ni-2Mo-LC |

445NF |

21Cr-0.3Ti-0.4Cu-Si,Nb |

B. Characteristics :

- Clean and beautiful surface

- Various surface treatments including mirror, matte, hairline, etching, embossing and painting

- High corrosion resistance and stain resistance

- Excellent abrasion resistance

C. Surface treatment :

|

Notation |

Surface Condition & Processing Method |

Use |

Photo |

|

No.2B |

When finishing acid cleaning by heat treatment or equivalent processing, temper cold rolling is performed till proper gloss is acquired (it shows better gloss and flatness than No. 2D) |

Common type of cold rolling products, used for general purposes |

|

|

No.4 |

Grinding is performed by No. 150 ~ 180 according to regulation of KS L 6001 (Grain size of abrasive). It shows smoother grind condition than No. 3 |

Construction, kitchen products, automobile, medical appliances, food facility, etc |

|

|

BA |

After cold rolling, dazzling heat treatment is performed to improve reflectivity and gloss |

Automobile parts, home appliances, kitchen products, decorations, construction, etc |

|

|

HL |

It uses abrasive, which has proper grain size, so that it can show continuous grinding pattern |

General products for construction material |

|

|

No.8 |

It has excellent gloss, reflectivity and sign of grinding by rotating buff using products over 800 Mesh (dry corrosion) |

Construction, reflector, substitution of platen, decorations |

|

|

MR |

It has high gloss, reflectivity and no sign of grinding by rotating buff using products over 1000 Mesh (dry corrosion) |

Construction, reflector, substitution of platen, decorations |

|

|

EM |

Cold rolling is performed by embossing roll, which has carved pattern engraved using etching or electric discharging |

Construction, interior for elevator, substitution of platen, electronic part, decorations |

|

|

BB |

After cold rolling, dazzling heat treatment is performed to give metallic luster |

General purpose, such as home appliances, kitchen products |

|